S

C

H

I

N

D

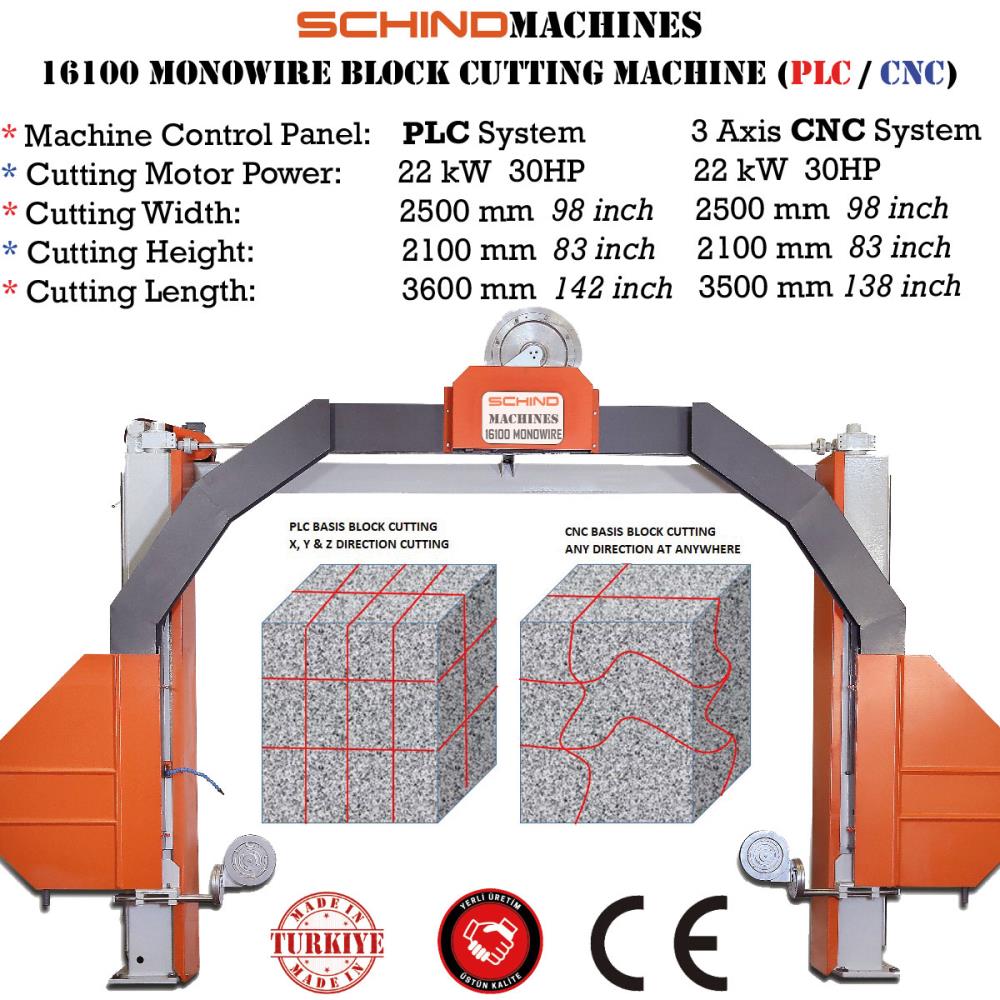

SCHIND 16100 Monowire Block Cutting Machine

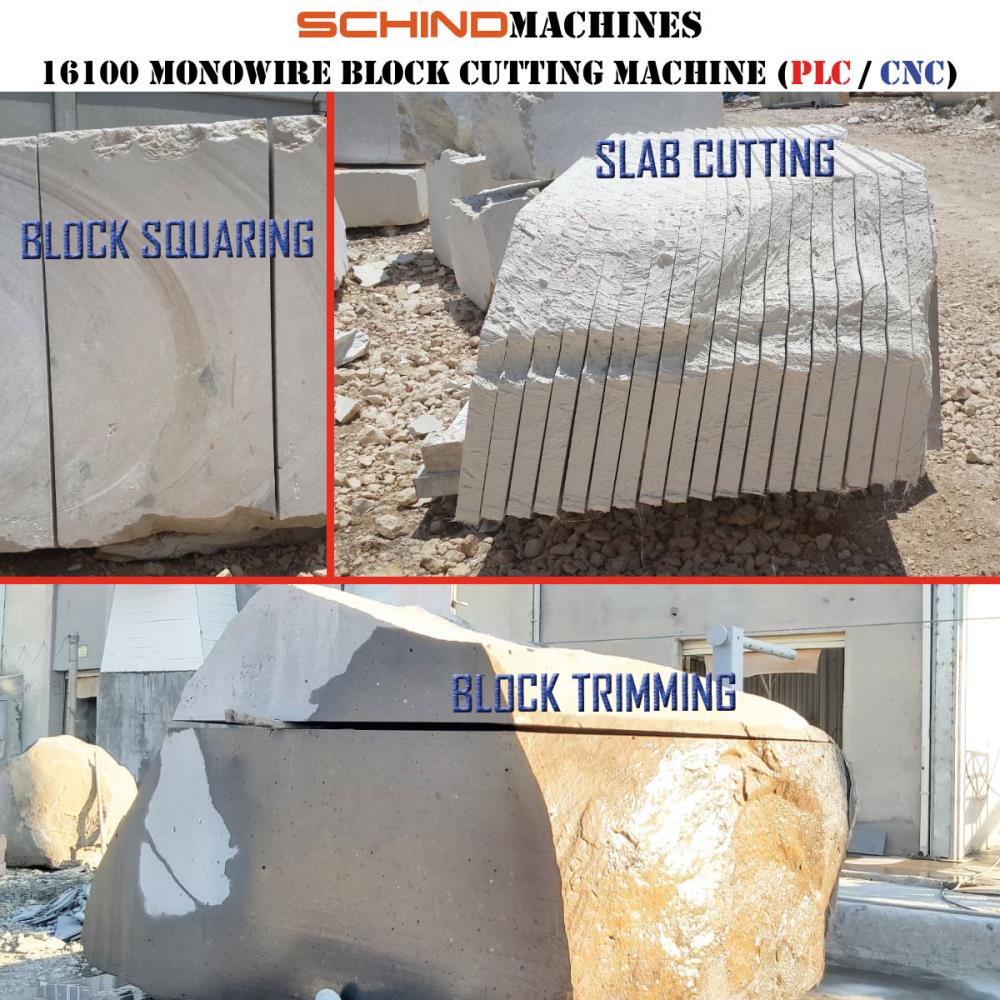

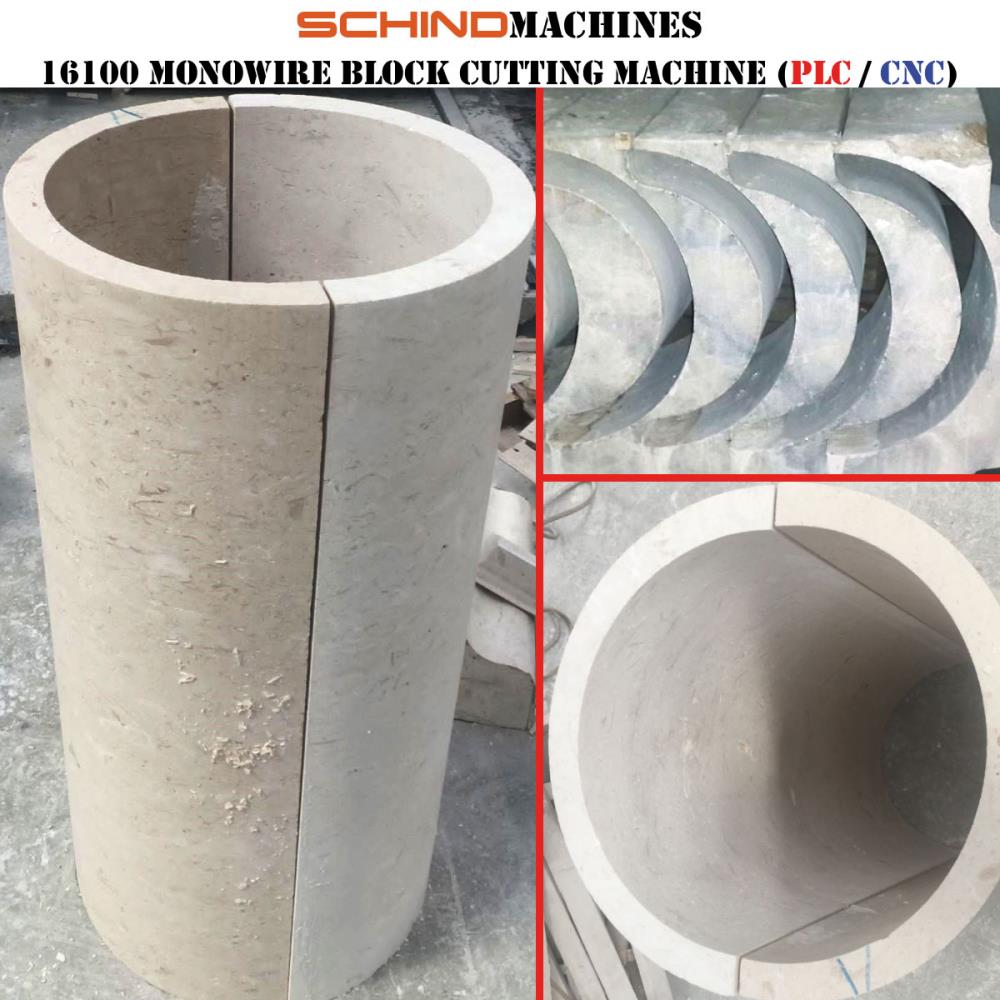

Schind 16100 single-wire gang saw machine is used to straighten the unformed blocks before cutting, to extract thick stone from blocks that are considered small for gang sawing, to obtain columns, to make piers, and to obtain canvas covers for columns.

- Homepage

- Machines

- Marble, Natural Stone and Granite Machines

- SCHIND 16100 Monowire Block Cutting Machine

SCHIND 16100 Monowire Block Cutting Machine

Schind 16100 single-wire gang saw machine is used to straighten the unformed blocks before cutting, to extract thick stone from blocks that are considered small for gang sawing, to obtain columns, to make piers, and to obtain canvas covers for columns.

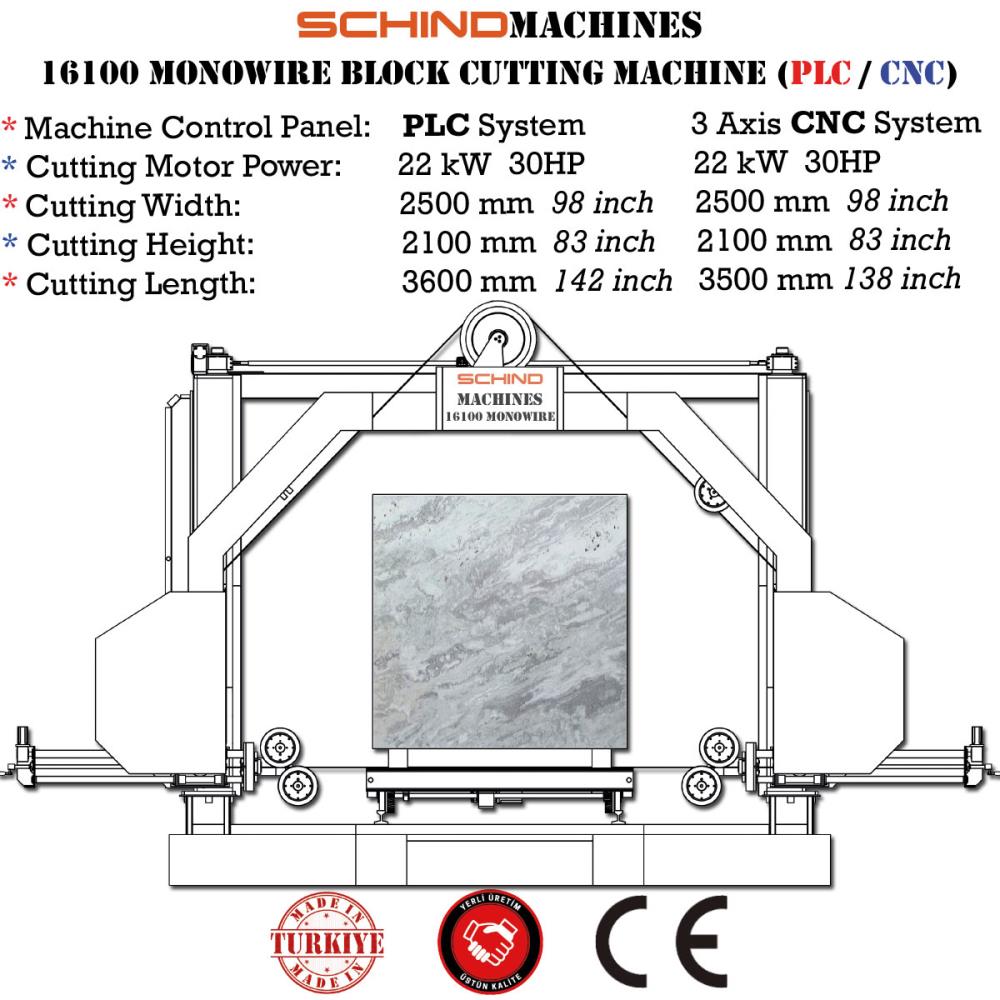

PRODUCT SPECIFICATIONS

| Product Code | SKA-100 |

| Origin | Turkey |

| Brand | Schind |

| Min Cutting Depth | 20mm |

| Slide Length | 6000mm |

| Motor Power | 22Kw |

| Machine Control System | PLC & CNC |

| Max Cutting Width | 3500mm width 2100mm height |

| Voltage | AC 380 V / 50 Hz, 30kW Total |

| Water Consumption | 40 Lt / min |

| Machine Dimensions (width - length - height) | 7100 x 1050 x 6600 mm |

| Machine Weight | 7.800 Kg ( PLC ) 8.600 Kg ( CNC ) |

MACHINE FEATURES

Cutting Speed: ~15cm – 40cm/hour (granite)~40cm – 100cm/hour (marble)

Diamond Wire Length: 17,300mm

Wagon Size: 2800mm – 2200mm

Wagon Load Carrying Capacity: 30 tons Option: Rotating wagon

Wagon Rail Length: 6000mm

Required Water Pressure: 2 Bar

Required Air Pressure: 7.5 Bar

Required Area for Installation: 600 cm X 900 cm.

It use to obtain marble in special shapes such as pillars base, columns, canvas marble sheets or to straighten shapeless blocks in quarry.

The wire tension is kept at ideal tension thanks to the pneumatic cylinder and sensor, and a constant cutting speed is achieved.

The up and down movements of the cutting system moving on the columns can be adjusted via the inverter.

Our machine with PLC module has 3 axes, CNC module machine has 4 axes.

Stress relieved strong chassis and 4 wheels with servo-controlled wagon movements allow us best cutting accuracy.

Programming can be done to get slices of different thicknesses from the same stone.

Since the positioning of the wagon & diamond wire is done electronically by laser, there will not be angular defect at the final product.

99 different cutting recipes can be saved in the program.

Simple user-friendly automation software is used.

The screen is touch-screen and shows the cutting axis and level to assists the operator.

It is painted with epoxy paint after sandblasting to prolong the life of our machine, which is exposed to high amount of corrosion.

Chain rotation is provided on special alloy 7000 series aluminum pulleys.

As a security measure; if the wire breaks, a special sensor connected to the tension roller will stop the machine immediately.

Transportation: 1 open top tent truck, overseas loading can be done as 1 open-top 40-foot container.

Installation:

Day 1. Machine layout planning

Day 2. Field leveling and concreting

Day 3. Machine installation

Day 4. Electrical installation

Day 5. Settings and program adaptations

Day 6. Trial cutting and training