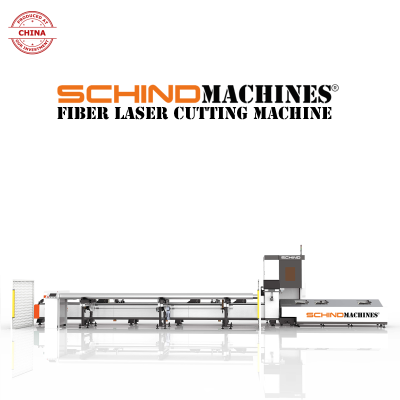

SCHIND SC-FHT Metal Sheet Fiber Laser Cutting Machine

With the Schind SC-FHT flat fiber laser cutting machine, you can make precise and accurate cuts. You can obtain powerful, fast and linear products with IPG Raycus and Maxphotonics resonator options and Raytools cutting head. CNC fiber laser cutting equipm

- Homepage

- Machines

- Fiber Laser Cutting Machines

- SCHIND SC-FHT Metal Sheet Fiber Laser Cutting Machine

SCHIND SC-FHT Metal Sheet Fiber Laser Cutting Machine

With the Schind SC-FHT flat fiber laser cutting machine, you can make precise and accurate cuts. You can obtain powerful, fast and linear products with IPG Raycus and Maxphotonics resonator options and Raytools cutting head. CNC fiber laser cutting equipm

PRODUCT SPECIFICATIONS

| Product Code | SC-FHT |

| Origin | Turkey |

| Brand | Schind |

| Laser Power | 1000w~6000w |

| Accuracy Of Positioning | ±0.03mm |

| Repeat Repositioning Accuracy | ±0.02mm |

| Max Movement Speed | 120m/min |

| Maximum Acceleration | 1.5G |

| Resonator | Raycus/Maxphotonics/IPG |

| Cutting Head | RayTools |

SCHIND Fiber Laser Cutting Machines

With the developing technology, fiber laser cutting machines are preferred in metal cutting. The main reasons for this are that fiber laser cutting machines take up little space, can cut quickly and reduce product consumption to a minimum.

As Schind Machines, we offer precise and safe solutions to users with our standard sizes and special production sizes in our fiber laser cutting machines. Thanks to our open chassis and closed chassis cutting machine options, we create safe environments in high power usage.

Thanks to our Maxphotonics, Raycus and IPG resonator options, we offer power options from 500 W to 15 KW. With Schind fiber laser cutting machines, materials such as steel, stainless steel, aluminum, copper, brass, carbon etc. can be cut. You can see the cutting thicknesses of our fiber laser cutting machines and the fiber laser resonators we use on our relevant machine pages.

Super heavy Steel Welding Machine Bed

The bed adopts 12mm super-thick monolithic steel plate laser blanking.The groove welding method is used to make the plates reach equal strength butt Then it undergoes stress annealing and natural aging treatment to eliminate internal stress and maintain the extremely high stability and cutting accuracy of the bed.

The Fifth-generation Aviation Aluminum Alloy Beam

The whole beam is processed by T6 heat treatment process to make the beam obtain the highest strength. Solution treatment improves the strength and plasticity of the beam, optimizes and reduces its weight, and speeds up the movement.

Double Pneumatic Chucks

The two-way pneumatic chuck tube automatically locates the center, extends the transmission structure to improve stable operation, and increases the jaws to save materials.

Auto focusing laser head

The auto-focusing optical fiber cutting head has a built-in motor drive unit. The focus lens is driven by a linear mechanism to automatically change the position within the specified range. The continuous focus can be set by the program to complete the rapid perforation of thick plates and automatically cut plates of different thicknesses and materials.

Intelligent Control System

CypCut plane cutting software is a set of software specially developed for the deep customization of the laser cutting industry, easy to use, rich in functions, suitable for various processing occasions.

Intelligent Central Control Lubrication

The time and frequency of lubrication can be adjusted through the central control system, and comprehensive multi-point lubrication for guide rails, sliders, screws, racks, etc., and automatic return and collection of waste lubricating fluid.

| Model | SC-FHT 3015 |

| Laser Power | 1000w~6000w |

| Working Area | 3050*1530mm |

| Accuracy Of Positioning | ±0.03mm |

| Repeat Repositioning Accuracy | ±0.02mm |

| Max Movement Speed | 120m/min |

| Maximum Acceleration | 1.5G |