PRODUCTION OF SPUR GEARS, HELICAL GEARS, SPIRAL BEVEL GEARS, WORM GEARS AND MOTION DRIVE MECHANISMS

We also produce spur gears, helical gears, straight bevel gears, worm gears, rack and pinion gear sets, timing gears, internal ring gears, clutch gears, power transmission and drive systems for our customers with whom we have mass manufacturing contract.

- Homepage

- Machines

- Contracting Mass Production, Contracting Metal Parts Manufacturing

- PRODUCTION OF SPUR GEARS, HELICAL GEARS, SPIRAL BEVEL GEARS, WORM GEARS AND MOTION DRIVE MECHANISMS

PRODUCTION OF SPUR GEARS, HELICAL GEARS, SPIRAL BEVEL GEARS, WORM GEARS AND MOTION DRIVE MECHANISMS

We also produce spur gears, helical gears, straight bevel gears, worm gears, rack and pinion gear sets, timing gears, internal ring gears, clutch gears, power transmission and drive systems for our customers with whom we have mass manufacturing contract.

SPUR GEARS

The most common type of gear has flat tooth surfaces aligned parallel to the axis of rotation when viewed from the shaft position. Straight-cut gears, cylindrical in shape and used to transmit mechanical motion, power, speed, or torque, are used in a wide variety of industrial technologies. We can manufacture spur gears from various alloys and produce them to the required hardness level, depending on the project.

HELICAL GEAR

Helical gears are cylindrical gears with obliquely angled tooth traces. Because helical gears have greater surface contact, they can transmit more power compared to spur gears. Helical gears are preferred for their superior performance compared to spur gears in terms of durability, less vibration, and a lower margin of error in mechatronics. Helical gears are classified as left-hand or right-hand helical depending on the direction of the teeth. We manufacture all types of helical gear sets on our precision CNC machines.

STRAIGHT BEVEL GEARS

Straight bevel gears have a straight tooth form and are used when two shafts are at a 90° angle to transmit power. Differentials, transmissions, and axles are some examples of mechanical systems where two non-parallel shafts transmit rotational motion. We can produce straight bevel gears used in many machinery and automotive spare parts.

SPIRAL BEVEL GEAR (CROWN WHEEL AND PINION GEAR)

A type of gear consisting of a cylindrical, conical, helical toothed bevel and pinion. Spiral bevel gears, also known as bevel pinions, are used to transfer power from a rotating shaft at 90° angles, such as in automotive differentials. Thanks to their helical structure, they are more efficient than straight bevel gears in terms of backlash, vibration, and performance. We manufacture spiral bevel gears with crown and pinion as transmission components for machinery and vehicles.

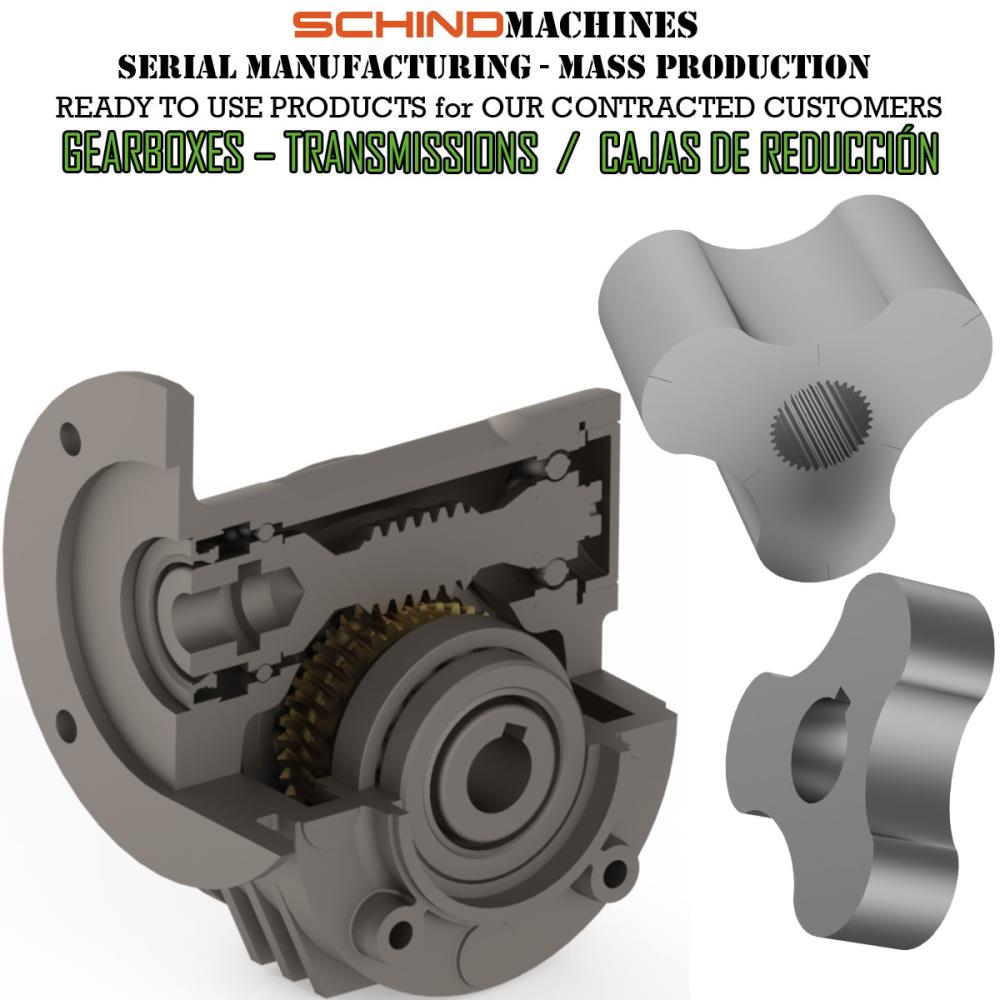

WORM GEAR SETS

Durable, self-locking worm gears are an ideal gear type for compact industrial designs. Available in our extensive range of standard and custom products, worm gears and gear sets are used to generate high speeds or torque. Worm gear sets transmit power at high speeds between non-intersecting shafts. They are generally used when high torque is needed after a high-speed reduction. Examples of worm gear sets include string tensioners in musical instruments, hose clamps, ship rudders, toy cars, and more.

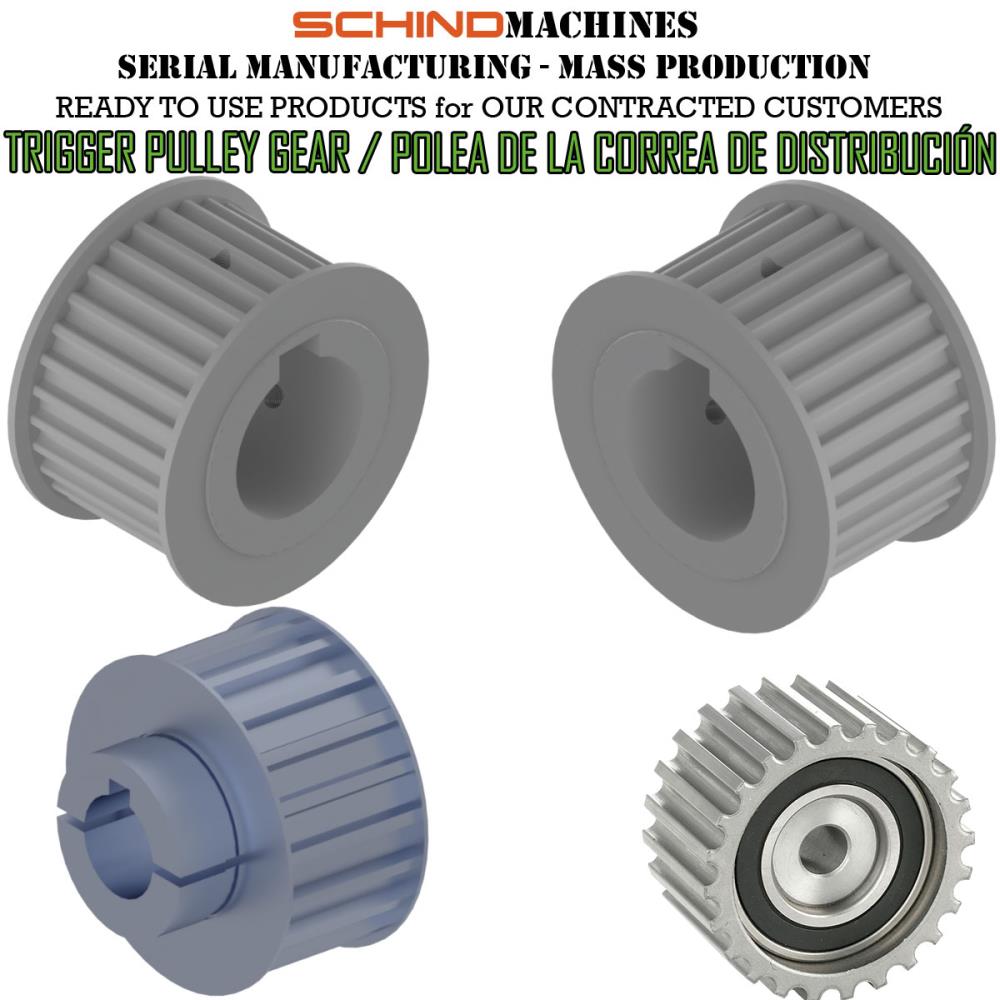

TRIGGER PULLEY GEAR

Trigger gear and pulley systems are used to precisely position the power to be transmitted. The timing gear is not used to transmit torque; it is used for positioning information and synchronizing movement in automation. Because the trigger pulley gear and belt teeth fit together perfectly, they prevent slipping. The trigger belt and pulley are an indispensable mechanical component for precise positioning of servo/stepper motor movements.

SPROCKET GEAR

Sprockets are used to transmit power from one shaft to another using a chain. Also known as chain wheels, they are used in machinery, bicycles, motorcycles, mass-produced loading and unloading, or moving conveyor systems. Because they must be resistant to abrasion, they must be made of high-quality steel and, if necessary, may be treated with heat treatment, hardening, or coatings such as zinc or black oxide. Our company produces sprockets in various diameters and thicknesses.

SHAFT GEAR (POW SHAFT)

Commonly used in motor vehicles, the shaft gear transmits power from the gearbox to the differential. It's a highly durable gear type that requires precision CNC machining and is resistant to dimensional errors. Similarly, the propeller shaft in marine vessels requires a shaft gear/tail shaft to transmit power to the propeller. Our CNC machines are capable of producing shaft gears of various lengths and diameters.

INTERNAL GEAR

Used in planetary gear systems that work with a central spur gear to achieve different torques and speeds. The internal gear moves in the opposite direction to the external gear that fits inside it. Internal gear is made from materials such as stainless steel, cast iron, steel, bronze, and cast iron. The choice of material depends on where the internal gear system will be used.

CUSTOM-MADE GEARS

As a result of special gear demands from our customers, we also produce gears of the desired diameter and hardness from different materials. With the advantage provided by our different machine lines used in our production, we are able to produce double helical gears (Herringbone Gear), composite gears, claw gears, clutch gear sets, rack gears, ball screws, ball bearing linear drive shafts and every parts of differential power transmission components.

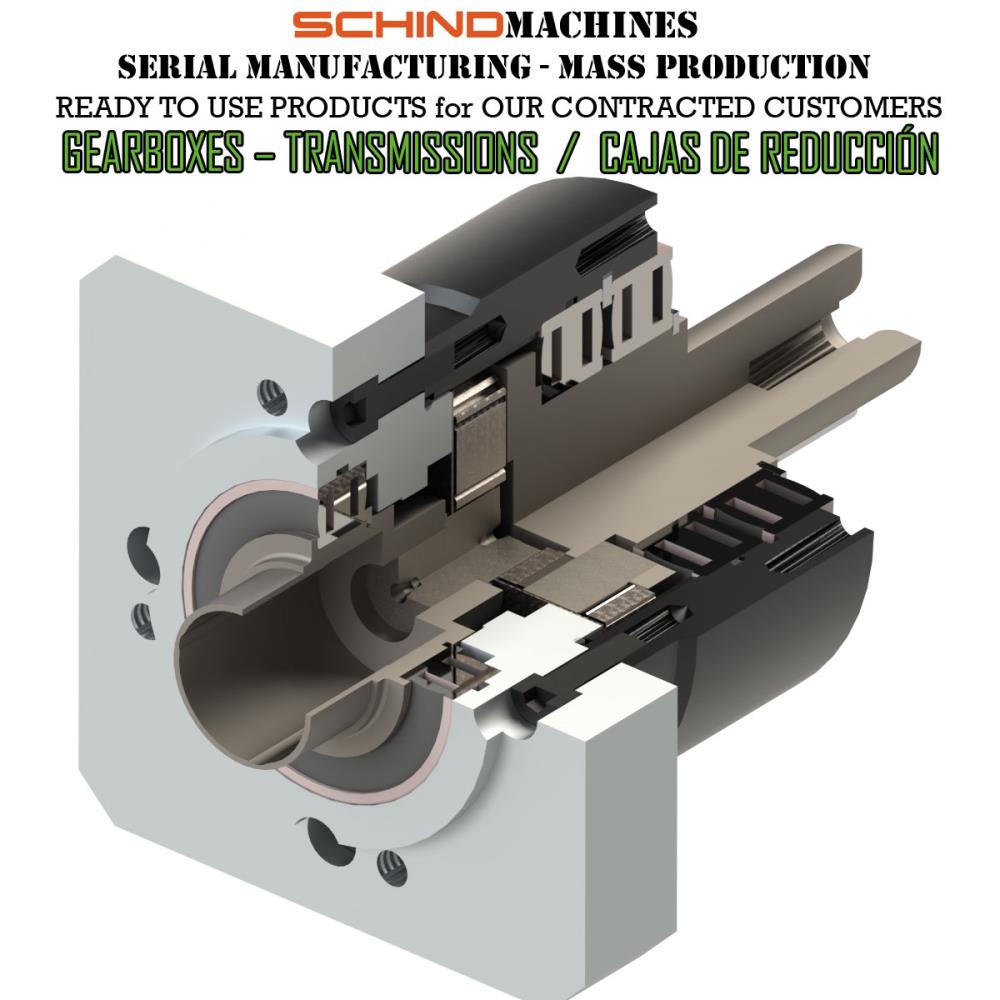

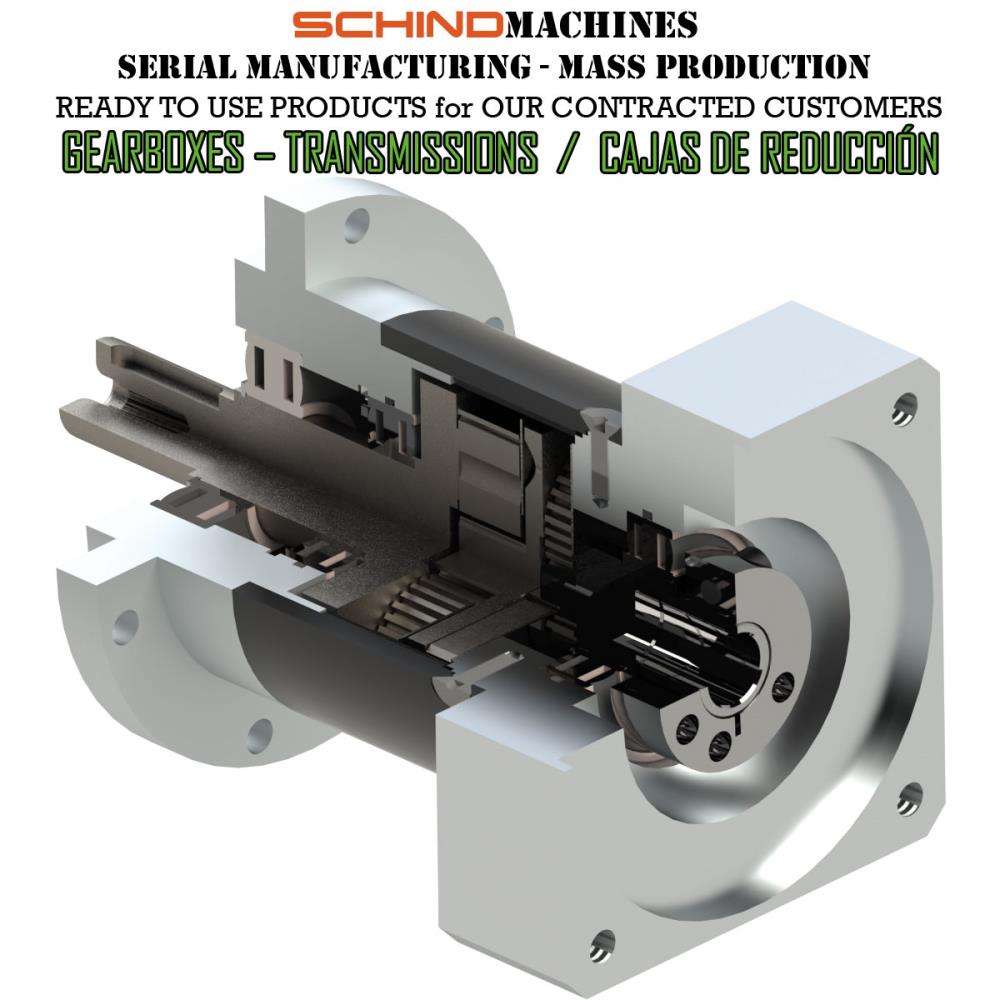

GEARBOXES – TRANSMISSIONS

Industrial gearboxes are power transmission systems that we design to meet the diverse needs of our customers from various sectors. As the most important machine, speed, or power component, gearboxes can provide a large amount of rotational force with a small amount of power, or conversely, slow down a high speed and increase torque. Our company designs and manufactures low and high-speed drive gearboxes of various types, including spur, helical, spiral bevel, bevel, worm, planetary gearboxes, harmonic, and cycloid gearboxes. We develop customized gearbox solutions for large-scale industrial applications requiring high efficiency, quiet operation, and high torque, as well as for heavy-duty industrial applications or automation systems requiring precise motion control